use of brinell hardness test|how to calculate brinell hardness : exporter exporters exporting The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to . Resultado da Siga os placares ao vivo para Konyaspor e outros resultados de futebol agora em Flashscore.com.br! Próximas partidas: 28.02. Besiktas x .

{plog:ftitle_list}

The Amazing Digital Circus HQ Pornô: Pomni, dese nhos de sexo com esta palhacinha. Safadinha que gosta de rola, admirando um pau grande na sua frente. Categorias .

In this article, we have seen the Brinell hardness test and its two different methods – Standard and Non-Standard Brinell hardness tests. Also, discussed its advantages, disadvantages or limitations, and applications.The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested .The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to .

The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test .Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The large size of indentation and possible damage to test-piece limits its usefulness.Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading . You should consider using the Brinell Hardness Test when: Testing Bulk Materials: It’s ideal for large and bulky materials where creating a large, averaged indentation is beneficial. Non-Uniform Hardness: When .

The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear .The Brinell method can be used for testing non-homogeneous materials (e.g. castings), because the large ball comes into contact with many crystals (different metallographic .Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information .Applications for Brinell Methods Brinell testing is suitable for measuring the hardness of rela-tively soft materials, including low-carbon steels, aluminum, lead, copper, and some plastics. The use of a large indenter and high load helps to minimize the effect of surface irregu-larities and yields more accurate hardness values. Soft Materials .

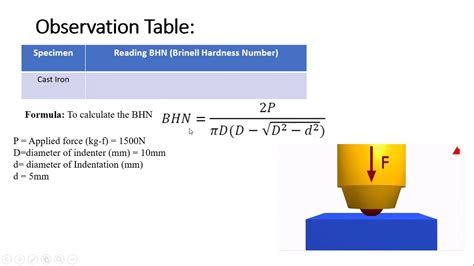

Application of Brinell Hardness Test in Various Industries. The Brinell Hardness Test finds extensive application across diverse industries, playing a crucial role in assessing material hardness and ensuring the quality and .Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the material being tested. The diameter of the indentation is then .

For both Vickers and Brinell hardness testing, it is common to use reference tables to give the value of hardness for a given indentation size and load, instead of making a calculation each time. 9.11.3 Rockwell hardness test. The third kind of test, mostly favoured in the USA, is the Rockwell hardness test. There are a number of variations of .Brinell Hardness Test. The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test uses a desktop machine to apply a specified load to a hardened sphere of a specified diameter. 1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information .

Hardness testing methods: Rockwell, Brinell and microhardness Heat treating has evolved into a highly complex, precise process that improves characteristics of metal parts. A critical component of quality heat treating is employing the correct hardness testing method to show manufacturers their parts achieve design requirements.The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The test is achieved by applying a known load to the surface of the tested material through a hardened steel ball of known diameter. The diameter of the resulting permanent impression in the tested metal is measured and the Brinell Hardness . 1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information .

The Brinell hardness test is an optical testing method for samples with coarse or inhomogeneous grain structure. This is the best test method for achieving the bulk or macro-hardness of a material, particularly those materials with heterogeneous structures.

The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically.In metallurgy: Testing mechanical properties .oldest of such tests, the Brinell hardness test, uses a 10-millimetre-diameter ball and a 3,000-kilogram load. Brinell hardness values correlate well with UTS.

Brinell Hardness Test. Brinell hardness test is one of the indentation hardness tests developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter hardened steel ball as an indenter with a 3,000 kgf (29.42 .

The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. .Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter .Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration .

quv test for paint

The typical brinell hardness test uses a 10 millimeters (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29 kN; 6,600 lbf) force. For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The indentation is measured and hardness calculated as: In the Brinell hardness test, we use a small ball (the indentor) made of tungsten carbide or steel to penetrate the material's surface, leaving a hemispherical indent. From the load/pressure on the indentor and the diameter of the hole it makes on the material surface, we can calculate its Brinell hardness number. .Units of hardness. There are a variety of hardness test methods in common use (e.g. Brinell, Knoop, Vickers and Rockwell). There are tables that are available correlating the hardness numbers from the different test methods where correlation is applicable.

Duration of Brinell and Rockwell Hardness; The Brinell test is very slow (30 – 60sec). Rockwell’s test is shorter (10 – 15sec). Calculation of Brinell and Rockwell Hardness; Brinell’s Hardness (HB) is the ratio of the applied force F (N) and the surface of the fingerprint S (mm 2): HBW = (F*0.102/ S); S = π* D* h.The Brinell hardness test was developed by the American Henry Brinell, who created the first tester in 1873. This is a widely accepted method in the field. The ASTM’s Brinell hardness test standard is used by alloy and metal suppliers and users, and it’s a basic requirement for all hardness testing equipment.Brinell hardness test is performed by measuring the value of the diameter of indentation produced by the indenter. Indenters. In the Brinell hardness test method, only one type of indenters is used while in Rockwell hardness we use two types of indenters for the procedure of the test. In the Brinell test, the intender is a calcareous ball or .Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).

Brinell hardness testing uses a known-sized ball with a diameter of 10mm and is pressed into the material with a specified amount of force. The smallest indentation made into the material is then measured and recorded. Based on the initial and final diameters of the indentation, the percent of density change can be calculated to determine the .The Brinell hardness test (HBW) serves as a crucial scale for quantifying material hardness, defined in ASTM E10 and BS EN ISO 6506-1 standards. This test involves pressing a Brinell indenter against a test specimen under a specified load and time duration. Typically, a hardened Tungsten steel ball, with varying force ranges based on material .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .

how to calculate brinell hardness

brinell hardness testing machine diagram

webCanal de TV para assistir Al Feiha x Al-Nassr. Este jogo da jornada 23 da época 2022/2023 Arábia Pro League (SPL) entre Al Feiha e Al-Nassr será transmitido para todo o mundo (exceto Arábia Saudita) no YouTube, Shahid. O Al Feiha defronta o Al-Nassr naquela que será a 23.ª jornada da Saudi Pro League (SPL) 2022/2023.

use of brinell hardness test|how to calculate brinell hardness